Machine Tool Technology

Institute of Innovation

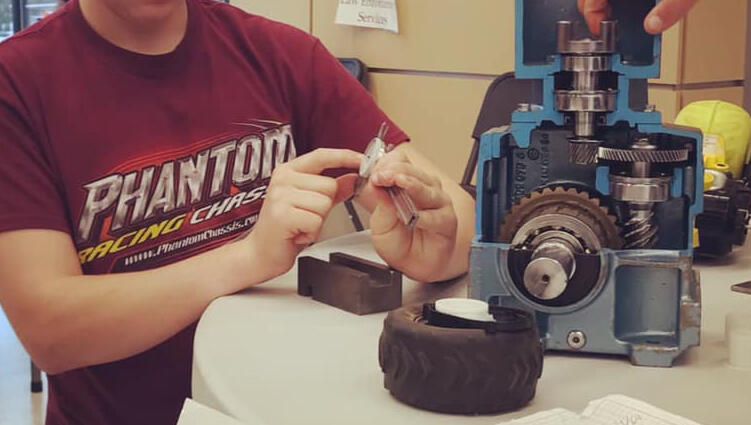

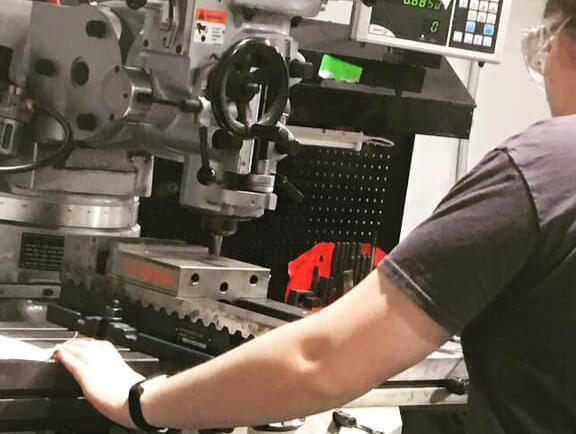

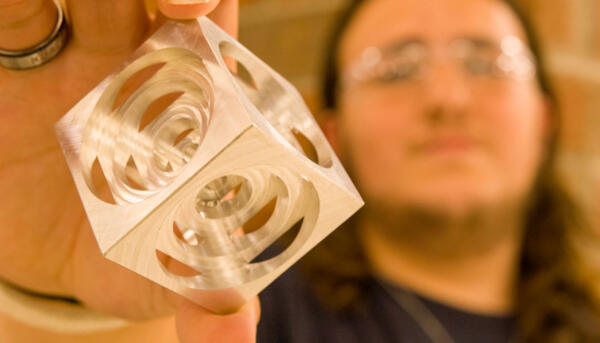

Machine tool technology students learn how to set up and operate standard machines to shape metal according to blueprint specification. Equipment used includes the following: lathes, mills, band saws, and measuring instruments. Students will gain knowledge in blueprint reading, precision measuring equipment operation, and computer numerical control (CNC) equipment.

Program Courses

Machine tool 3

Detailed process planning. Further application in geometric dimensioning & tolerancing. CNC mill & lathe programming. Surface grinding, horizontal spindle, & reciprocating table. Process adjustment & improvement.

Machine tool 4

Process planning that includes quality plan for a part requiring milling, drilling, turning, or grinding. Taper reaming & pipe tapping. Analyze performance of single-part production process Career management.

Job Opportunities

Machinist

$22.62/hr -- 47,047/yr

Set up & operate machine tools to produce precision metal parts.

Millwrights

$26.40/hr -- 54,920/yr

Install, maintain, & repair factory equipment & industrial machinery.

Mechanical Engineer

$43.35/hr -- $90,160/yr

Ensure construction meets codes & contract specifications.

Production Manager

$52.30/hr -- $108,790/yr

Oversee the daily operations of manufacturing & related plants.

Get in touch

Share your name, email, and a brief message, and the instructor for this program will respond to you.